How Does the Water Treatment Plant Work?

Water Intake and Pre-treatment

How does the water treatment plant work – The initial stages of water treatment involve obtaining raw water and preparing it for further processing. This includes various methods of water intake and pre-treatment steps to remove large debris and improve the water’s clarity and treatability.

Water Intake Methods

Water intake methods vary depending on the water source’s availability and characteristics. Common methods include river diversions, where water is channeled from a river; lake intakes, which involve drawing water from a lake; and wells, which extract groundwater. Each method requires specific infrastructure and considerations regarding water quality and environmental impact.

Screening is a crucial initial step, removing large debris like branches, leaves, and trash using bar screens or fine mesh screens. This prevents damage to downstream equipment and improves the efficiency of subsequent treatment processes.

Pre-treatment Processes

Pre-treatment aims to remove suspended solids and improve the water’s coagulability. This typically involves coagulation, flocculation, and sedimentation.

Coagulation uses chemicals, such as alum (aluminum sulfate) or ferric chloride, to neutralize the charges of suspended particles, causing them to clump together. Flocculation gently mixes the coagulated water to encourage the formation of larger flocs. Sedimentation then allows these heavier flocs to settle out of the water under gravity.

Comparison of Pre-treatment Methods, How does the water treatment plant work

Source: theconstructor.org

| Method | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|

| Coagulation-Flocculation-Sedimentation | Removes a significant portion of suspended solids, relatively inexpensive | Requires careful chemical dosing, sludge generation | Municipal water treatment, industrial wastewater treatment |

| Direct Filtration | Faster process, less land requirement | Less effective for highly turbid water, higher chemical demand | Smaller water treatment plants, water with low turbidity |

| Dissolved Air Flotation (DAF) | Effective for removing oil and grease, produces less sludge | Higher energy consumption, more complex equipment | Industrial wastewater treatment, removal of oil and grease |

Coagulation and Flocculation

These two processes are crucial for removing suspended solids from water before further treatment. They rely on chemical reactions to bind small particles together, forming larger, settleable flocs.

Chemical Reactions in Coagulation and Flocculation

Coagulants, such as alum or ferric chloride, react with the negatively charged particles in the water, neutralizing their charges. This allows the particles to overcome their electrostatic repulsion and collide, forming larger aggregates. Flocculation involves gentle mixing to enhance these collisions and accelerate the formation of larger flocs.

The effectiveness of coagulants depends on factors like water pH, temperature, and the type and concentration of suspended solids.

Comparison of Coagulants

- Alum (aluminum sulfate): Effective over a wide pH range, relatively inexpensive, but can produce a slightly acidic effluent.

- Ferric chloride: Effective at lower pH levels, faster coagulation, but more expensive than alum.

- Ferric sulfate: Similar to ferric chloride but less corrosive to equipment.

- Polymeric coagulants: Highly effective in removing specific types of suspended solids, often used in conjunction with inorganic coagulants.

Visual Representation of Coagulation and Flocculation

Imagine tiny particles dispersed throughout the water. The addition of a coagulant neutralizes their negative charges, allowing them to clump together. Gentle mixing during flocculation encourages these clumps to grow larger, forming visible, fluffy flocs that settle easily.

Sedimentation and Filtration

After coagulation and flocculation, sedimentation and filtration are employed to remove the remaining suspended solids and improve water clarity. These processes work on different principles to achieve a high level of water purification.

Sedimentation

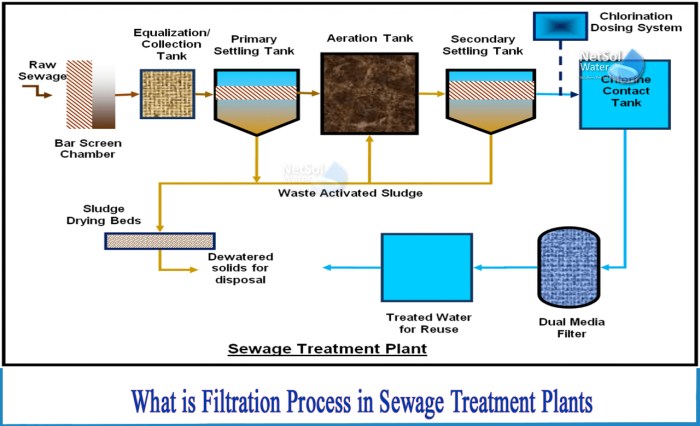

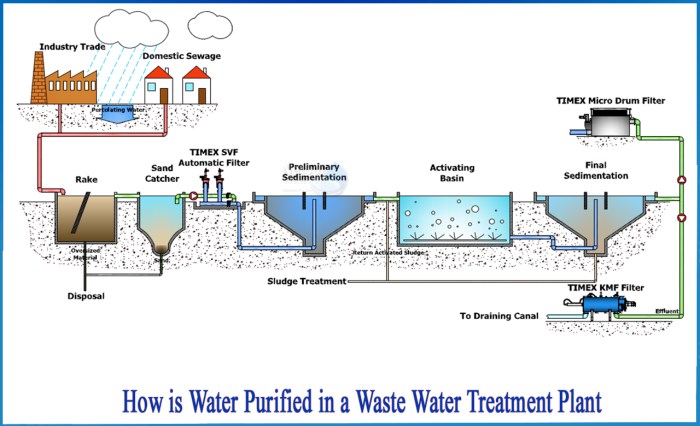

Source: netsolwater.com

Sedimentation is a gravity-driven process where water is held in large basins, allowing the heavier flocs to settle to the bottom. The efficiency of sedimentation depends on factors like the settling velocity of the flocs, the residence time of the water in the basin, and the flow rate. The settled sludge is periodically removed.

Filtration Methods

Filtration uses porous media to remove remaining suspended solids that escaped sedimentation. Common filter types include sand filters, gravel filters, and membrane filters. Sand filters are widely used, employing layers of sand and gravel of varying sizes. Membrane filters, such as microfiltration and ultrafiltration, offer higher removal efficiency for smaller particles and pathogens.

Filtration Process

- Water enters the filter bed from the top.

- Larger particles are trapped in the upper layers of the filter media (gravel).

- Smaller particles are trapped in the finer layers (sand).

- The filtered water passes through the filter bed and is collected at the bottom.

- Periodically, the filter is backwashed to remove accumulated solids and restore its filtration capacity.

Disinfection

Disinfection is a critical step to eliminate harmful microorganisms, ensuring the safety of the treated water. Several methods are employed, each with its advantages and disadvantages.

Disinfection Methods

Source: netsolwater.com

Common disinfection methods include chlorination, UV disinfection, and ozonation. Chlorination uses chlorine gas or hypochlorite to kill bacteria and viruses. UV disinfection uses ultraviolet light to inactivate microorganisms. Ozonation employs ozone gas, a powerful oxidant, to destroy pathogens.

Comparison of Disinfection Methods

| Method | Effectiveness | Drawbacks | Typical Applications |

|---|---|---|---|

| Chlorination | Effective against a broad range of microorganisms, relatively inexpensive | Can form disinfection byproducts (DBPs), requires residual chlorine monitoring | Municipal water treatment, wastewater disinfection |

| UV Disinfection | Highly effective against bacteria and viruses, no DBP formation | Less effective against some resistant microorganisms, requires regular lamp replacement | Municipal water treatment, wastewater disinfection |

| Ozonation | Very effective against a wide range of microorganisms, no DBP formation | Expensive, ozone is unstable and requires on-site generation | Municipal water treatment, wastewater treatment, industrial applications |

Residual Disinfectant Monitoring

Residual disinfectant levels are continuously monitored using automated sensors and regular laboratory testing. Maintaining a sufficient residual throughout the distribution system ensures ongoing protection against microbial contamination.

Water Storage and Distribution

After treatment, water is stored in reservoirs before distribution to consumers. Efficient storage and distribution are crucial for maintaining water pressure and ensuring reliable service.

Water Storage Reservoirs

Water storage reservoirs are designed to meet peak demand and provide a buffer against fluctuations in water supply. Factors influencing reservoir design include storage capacity, water quality protection, and site characteristics. Reservoirs are typically designed with multiple compartments and overflow mechanisms to ensure safety and prevent contamination.

Water Distribution

Water is distributed from the treatment plant to consumers through a network of pumps and pipelines. Pumps maintain water pressure throughout the distribution system, ensuring adequate flow to all areas. The pipeline network is designed to minimize water loss and ensure efficient delivery.

Safety Measures

- Regular inspection and maintenance of reservoirs and pipelines.

- Protection of reservoirs from surface runoff and contamination.

- Implementation of disinfection procedures during pipeline maintenance.

- Monitoring of water quality throughout the distribution system.

Water Quality Monitoring and Testing

Continuous monitoring and testing are essential to ensure the treated water meets regulatory standards and maintains its quality throughout the distribution system. This involves regular testing of various water quality parameters.

Key Water Quality Parameters

Key parameters monitored include pH, turbidity, temperature, chlorine residual, bacterial counts (e.g., coliforms), and various chemical constituents. The frequency of monitoring depends on the regulatory requirements and the specific characteristics of the water source and treatment process.

Water Quality Testing Methods

Methods for testing water quality parameters include standard laboratory procedures such as titrations for pH and chlorine, spectrophotometry for turbidity, and microbiological tests for bacterial counts. Automated online monitoring systems are increasingly used for continuous real-time monitoring of key parameters.

Water Quality Monitoring Flowchart

A flowchart would begin with “Raw Water Intake,” proceed through each treatment stage (coagulation, flocculation, sedimentation, filtration, disinfection), with testing points at each stage and a final quality check before storage and distribution. The flowchart would include feedback loops to adjust treatment processes based on test results, and a final output indicating whether the water meets standards.

Sludge Management

Water treatment generates various types of sludge, which require proper management to minimize environmental impact. Effective sludge management involves various treatment and disposal methods.

Types of Sludge

Sludge types include primary sludge (settled solids from sedimentation), secondary sludge (biological solids from wastewater treatment), and filter backwash water. Each type has different properties, such as moisture content, organic matter content, and potential pathogens.

Sludge Treatment and Disposal

Sludge treatment methods include dewatering (reducing moisture content), anaerobic digestion (breaking down organic matter), and stabilization (reducing pathogen levels). Disposal methods include land application (after appropriate treatment), incineration, and landfill disposal. The choice of method depends on regulatory requirements, cost considerations, and environmental impact.

Sludge Management Equipment and Processes

Sludge management involves specialized equipment such as thickeners, centrifuges, digesters, and incinerators. Processes include sludge conditioning (improving dewaterability), dewatering, and disposal. Careful management is crucial to minimize environmental impact and comply with regulations.

FAQ Section: How Does The Water Treatment Plant Work

What happens to the sludge removed during treatment?

Sludge undergoes various treatments like dewatering, digestion, and sometimes incineration before safe disposal or repurposing.

Water treatment plants purify water through a series of processes, ensuring it’s safe for consumption. Understanding this process helps us appreciate the journey water takes before reaching our taps. Interestingly, this contrasts with the needs of aquatic plants; to learn more about whether or not these plants require soil for growth, check out this informative article: do water plants need soil.

Returning to water treatment, the final stage often involves disinfection, guaranteeing the water is free from harmful microorganisms before distribution.

How often is water quality tested?

Water quality is continuously monitored and tested at various points throughout the treatment process and in the distribution system, following strict regulatory guidelines.

What are the common types of disinfectants used?

Common disinfectants include chlorine, chloramine, ozone, and ultraviolet (UV) light, each with its own advantages and disadvantages.

How is the water pressure maintained in the distribution system?

Water pressure is maintained through a network of pumps strategically placed throughout the distribution system, ensuring consistent water delivery to consumers.